My fascination with bushwalking stoves has driven me to what is possibly a first for a hobby stovie, I have made myself a stove flame profiler which can do 1D and 2 D profiles of a backpacking stove flame.

Flame profiler rig

I have been planning this flame profiler for a few years now and I have been collecting bits and pieces since, I started to build the profiler about a 18 months ago but due to distractions the development stalled several times, the profiler project is still in its early days and as I am learning from it, I still have some development and improvements to do.

I wish to thank my friends Tony, Mike, Andrew and Mark (sadly no longer with us) for their help, but I would specially like to thank Peter for his top level programming skills, without the help and equipment gifts from these highly skilled people this flame profiler project would have never been possible.

The Flame profiler is an X-Y traversing system that can move a heat exchanger with a high temperature thermocouple temperature probe in the middle of the heat exchanger, the temperature data can be logged and recorded for analyzing with a 2D or 3D graphing program.

Heat exchanger

Details

The heart of the system is the X-Y traversing system, the traverser was started with being given some stepper motors and part from an old plotter which has about 600 mm travel, this has become the Y traversing system, it is driven by wire rope wrapped around a pulley and the propulsion is by a stepper motor. The X traversing system is made from an old linear bearing rail, for the X system I have made my own wire rope propulsion system, it is also driven by a stepper motor, the X system still needs some development but works OK for now.

Heat exchanger

The heat exchanger is made from an old saucepan which has a base diameter of 206mm, the base is 6mm thick and the temperature probe is located in the middle, the heat exchanger is filled with water which is conditioned with water pumped through some copper tubing which is coiled inside, conditioned water is pumped through the copper coil. I made the current heat exchanger system as a trial system as I was not sure what was needed and while this heat exchanger system while it works quite well, for some alcohol stoves the 206mm diameter is a bit small and the water conditioning system is a bit crude. I am planning a larger heat exchanger of around 400mm diameter with a direct flow through of the conditioning water but I am surprised how well the copper coil system works so I will doing some more thinking on the new heat exchanger design.

Stove platform

At the moment the stoves being tested sit on very crude adjustable height platform, the base of this system sits on an old computer case and an old car jack which gives me the ability of an easily adjustable height, while for now the system works, improvements to this setup will be high on my priorities to improve.

Temperature probe and signal conditioning

The temperature probe is home made from a K type thermocouple, the thermocouple wire is threaded through a piece of ceramic tube with two holes through it.

The thermocouple signal is conditioned through a modified Jaycar Electronics high temperature thermocouple kit, this kit converts the very small thermocouple voltage into a voltage that can be read by the data acquisition system, at the moment the maximum temp that I can read is 1043 degrees C. I am not that happy with the thermocouples response time, I am going to try and improve this by making my own thermocouple with a smaller tip.

The conditioned data signal is then input into a National Instruments USB-6008, 12-Bit, 10 kS/s Low-Cost Multifunction DAQ A-D board, the voltage signal is then converted into temperature degrees ºC with a program written with Labview 7.

The Stepper motors are also controlled with a program written with labview through the parallel port, the profiler control program and data logging program are linked to the same timing.

The tests that I have done so far have been 1D and 2 D profiles, with the 1D profiles I ran the probe at 1mm per second and logged 1 sample every second

The 2D profiles, I ran the probe over in a matrix of 5mm x 5mm in a 100mm x 100mm square, the data was graphed in 3D using Mathmatica, I am new to this program and need do some more learning to make the graphs look better.

Why have I made a flame profiler? I am interested in understanding stove design and I think the profiler will help in this endeavor.

Some result so far

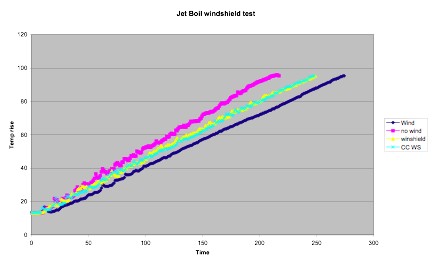

Below is a 2D graph of a 1D pass over a JetBoil stove with the probe protruding 4mm, 2mm and the tip flush with the bottom of the heat exchanger, note the large difference in temperatures.

profile of Jetboil stove with different tip protrusion lenghts

Below is a 3D graph of the flame pattern of a JetBoil stove, what confused me here is the high and low temperature pattern in a cross, after some thought I pulled the burner head apart and as can be seen from the photo below the baffle inside has four support legs, even though the legs are relatively small it can be seen from the graph they have a reasonable large influence on the flame pattern.

JetBoil flame pattern

I still have to fully understand what is going on with the information that the profiler is giving me, but I hope that will come. I will post more results for different stoves on my blog soon.

Read Full Post »